Concrete Maturity is proven method of accurately estimating in-situ concrete strength. The Maturity of concrete indicates how far the curing process has progressed as the strength development is temperature and time-dependant.

What is Concrete Maturity?

Concrete Maturity is a proven, relatively simple method of accurately and reliably determining the in-situ strength of concrete. It is based on the principle that for a given mix/recipe, the strength is directly related to its Maturity (temperature history).

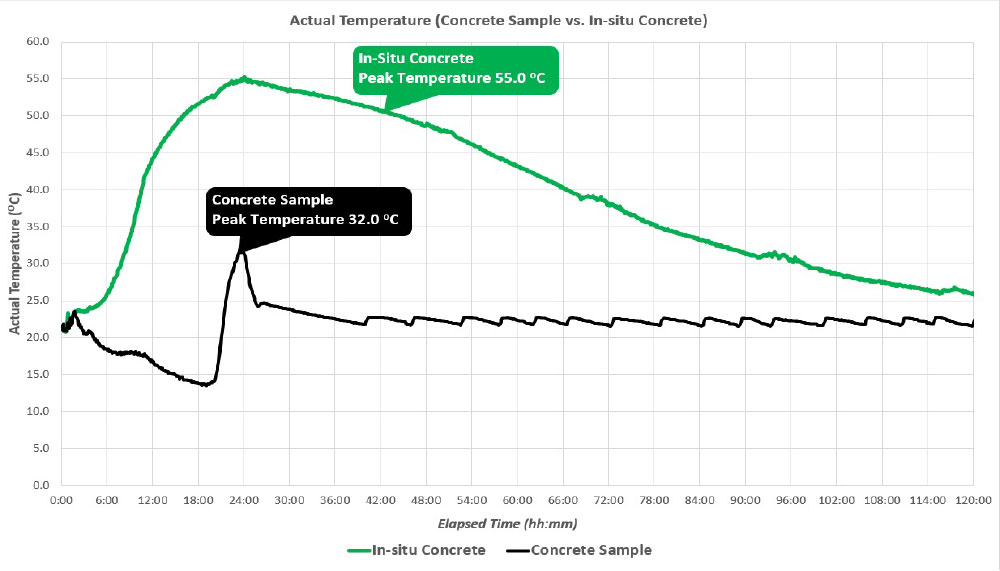

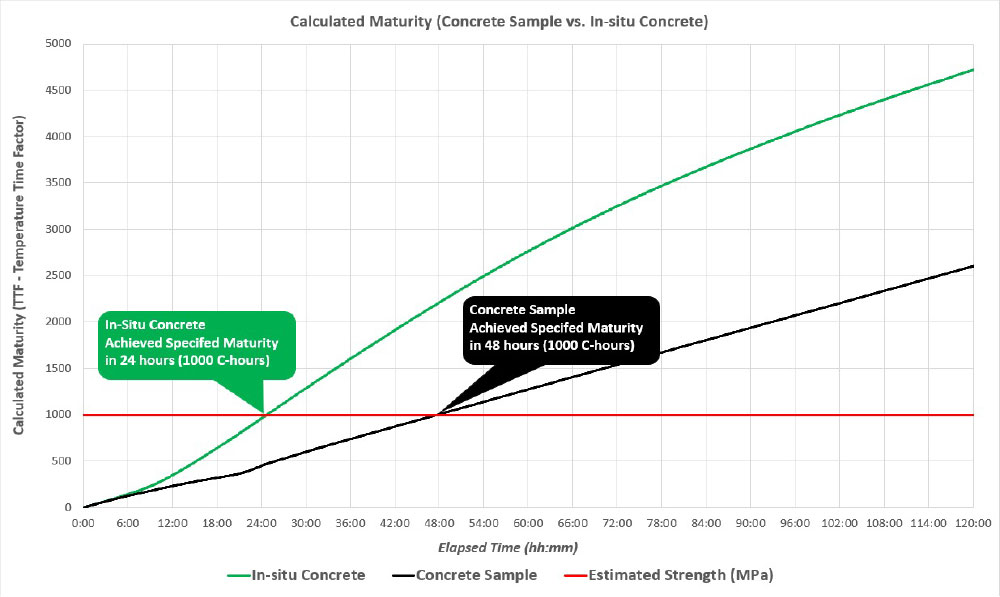

The concrete’s Maturity is calculated based on the temperature generated and retained over a period of time. In the early ages of the curing cycle, an exothermic reaction occurs, which generates heat. As the exothermic reaction increases, so does the temperature of concrete, which is directly related to the volume of concrete.

How is the strength of in-situ concrete currently established?

The use of concrete test cylinders cured in various ways is by far the most common method used to try and establish the in-situ strength of concrete. Concrete cylinder tests are designed for compliance testing, i.e. to ensure that the concrete supplied and placed is of the required quality. The tests require that the specimens are cured on-site for an initial period, typically 18 – 36 hrs, before they are removed from the site and placed in curing baths at a controlled temperature for specific periods, e.g. 7, 28 days, etc.

These test specimens are relatively small (approx. 1.5 L), have a large surface area to volume ratio, and their temperatures are controlled by the curing conditions. In comparison, the in-situ concrete has a substantially larger volume, the surface area to volume ratio is significantly lower, and the environment has substantially less impact on limiting the temperatures.

As a result of this Maturity and therefore compressive strength in test cylinders varies substantially from that in the in-situ concrete. While many authorities have tried different methods of curing concrete test specimens cylinders, e.g. keeping these on the element, under tarps, etc., to try and replicate the in-situ Maturity, none of these can accurately or reliably represent the in-situ conditions.

What is the difference between Concrete Maturity and the Standard destructive test methods?

When using the Concrete Maturity Method, the in-situ properties such as compressive strength are accurately and reliably represented, and standard destructive methods provide inaccurate and misleading information. The graphs below clearly demonstrate the differences in temperatures and Maturity.

As a result, test cylinders can not accurately represent the in-situ strength of the concrete. Further to this, the relationship is not consistent, and while cylinders often substantially underestimate in-situ strength, there are also many instances when they overestimate in-situ strength. This leads to decisions being based on flawed information, increased risk, increased costs, unnecessary delays, missed opportunities, etc.

Importance, Applications and Benefits of Maturity?

Concrete construction is highly time-dependent, margins are tight, and there is a significant move to reduce carbon footprints and increase sustainability. To achieve these and other objectives requires accurate, readily available and reliable information. Concrete Maturity achieves this and addresses the issues associated with standard cylinders. As a result, it opens up significant opportunities to:

- Accelerate construction

- Optimise concrete products and reduce concrete costs

- Reduce testing costs

- Increase visibility and project planning, e.g., visibility of strength development and when elements will achieve targets, allowing you to take advantage of these in real-time.

- Increased sustainability, e.g. lower total and Portland cement contents, higher replacements of Portland cement with supplementary cementitious materials (SCM’s), e.g. fly Ash, Slag. It should be noted that the hydration rates and strength development of SCMs are slow at standard curing conditions. However, they increase significantly with higher curing temperatures, e.g. in-situ concrete temperatures. Concrete Maturity allows these benefits to be realised.

- Reduced risk, in many cases, standard test cylinders are substantially (40% or more) underestimating the in-situ compressive strength. However, sometimes they overestimate the in-situ strength, which leads to the risk of personal injury, damage, repairs, etc., e.g. when post-tensioning anchors fail.

All very beneficial in a highly competitive, cost and time-driven business under significant pressure to improve safety, reduce carbon footprints, and increase sustainability.

Concrete Maturity is relevant for any application where accurate estimates of in-situ concrete performance is required. These include:

- Removal of formwork and props

- Trafficking pavements, loading structures, etc.

- Jumping forms

- Saw cutting times

- Post-tensioning.

- Precast

- Steam curing

- Reducing carbon footprints and increasing sustainability

ConXedge: Experts In Concrete Maturity Testing and Thermal Management of Concrete

The ability to accurately and reliably determine when the required properties, e.g. compressive strength, are reached at the earliest possible moment with the least effort is invaluable. ConXedge uses smart sensors to collect in-place temperatures and a powerful web application to calculate Maturity, analyse performance and determine when targets have been achieved. ConXedge includes a comprehensive solution for concrete Maturity, mass concrete and critical site conditions, e.g. evaporation rates in real-time. With conXedge, you can maximise profits, minimise risk and increase sustainability. Call +61 (0) 2 8315 8440 and talk to our team today, or visit our website to leave your details for us to get in touch with you.

There is no doubt that the way concrete is assessed with test cylinders has its limitations and flaws. Next month, we will be discussing how the relationship between strength and Maturity is established using different calculations.